At Sedgbeer, we design, manufacture and install cost effective, stainless steel conveyors, fitted with hygiene compliant belting, tailored to your exact requirements. Our equipment is well built, offering a reliable and low maintenance conveyor solution for all areas of food production and packaging.

All of our conveyors are manufactured in our UK based facilities and are fully constructed from stainless steel and other food safe materials, ensuring all our belts are hygiene compliant. We utilise high quality components along with proven build methods to produce reliable conveyor systems.

We can design conveyor belts for many applications, such as transporting:

- Food from one process to another

- Cut up/portioned product

- Whole birds

- Feathers

- Packaged goods

- Crates

We understand how important ease of maintenance is, so all our conveyors feature remote grease lines. Bearings, drive, idle rollers and motor gearboxes are designed to be easily removed and re-fitted for maintance to reduce down time.

The efficiency of cleaning is a major issue for food processing facilities, we design all our conveyors for easy cleanability and can also fit clean-in-place (CIP) units to belts. The ability to easily clean and inspect all equipment areas without any heavy lifts contributes to a consistent result.

Food products which can be handled by Stainless Steel conveyors:

- Poultry – Chicken, Turkey and Duck

- Meat – Beef, Lamb and Pork

- Fish and Seafood

- Halal products

- Frozen foods

- Chilled, raw and fresh ingredients

- Fruit and vegetables

- Bakery products

- Confectionery

Conveyor Types

Conveyor systems are key to any food processing operation, they transport materials and product quickly and easily, by replacing manual conveying processes, conveyor belt systems increase the efficiency and continuity of material and product flow in a processing plant.

Inclined Belt Conveyors

Inclined belt conveyors are used when products must be transported upwards. They can be designed with varying flight heights and pitches along with either TPU or plastic modular belting.

Decline Belt Conveyors

Decline belt conveyors are used when products must be transported downwards. They can be designed with varying flight heights and pitches along with either TPU or plastic modular belting.

Flat Belt Conveyors

Flat belt conveyors the most common conveyor type, used for moving product around processes. Flat belt conveyors are ideal for use as stand-alone units, process lines or for integration with other machinery.

Transfer Conveyors

Transfer conveyors are designed for the transference of products/materials to other belt systems..

Gravity/Roller Conveyors

Gravity conveyors are unpowered conveyors such as a roller conveyor that uses gravitational force to move materials over a downward path.

Roller conveyors have many different applications including transporting trays, crates, plastic boxes, cardboard boxes, plastic totes and poly-bags.

Belt Accessories

We can also incorporated the following belt features and accessories:

- Clean-In-Place (CIP) units

- Scrapers

- Profiles / Cleats

- Tracking guides

- Flights

- Sidewalls

What are the benefits of adding a conveyor system to your factory?

- Reduced personnel

- Improved production output

- Manual handling is reduced

- Create space / storage / buffer areas

- Allows for elevation to upper level for increased production space

- Increased productivity

- Reduced operating costs

- Potential to improve hygiene

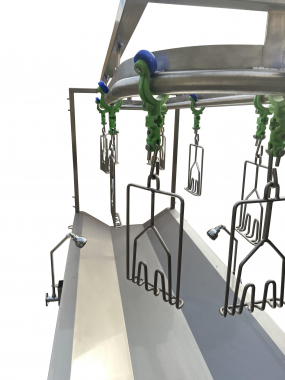

We have experience supplying conveyors for all aspects of the meat processing application including deboning cone lines, cutting lines, feather removal and packaging lines.

Get in touch with us today to discuss your project.